Surface Jet Aerators

JM Series Surface Jet Aerators

Jet Aerator

Features

- High velocity below surface aeration.

- Superior mixing.

- Increased dissolved oxygen levels.

- Energy and maintenance cost reduced.

Applications

- Aerated lagoons.

- River and canal restorations.

- Oxidation ditch.

- Aeration Tank.

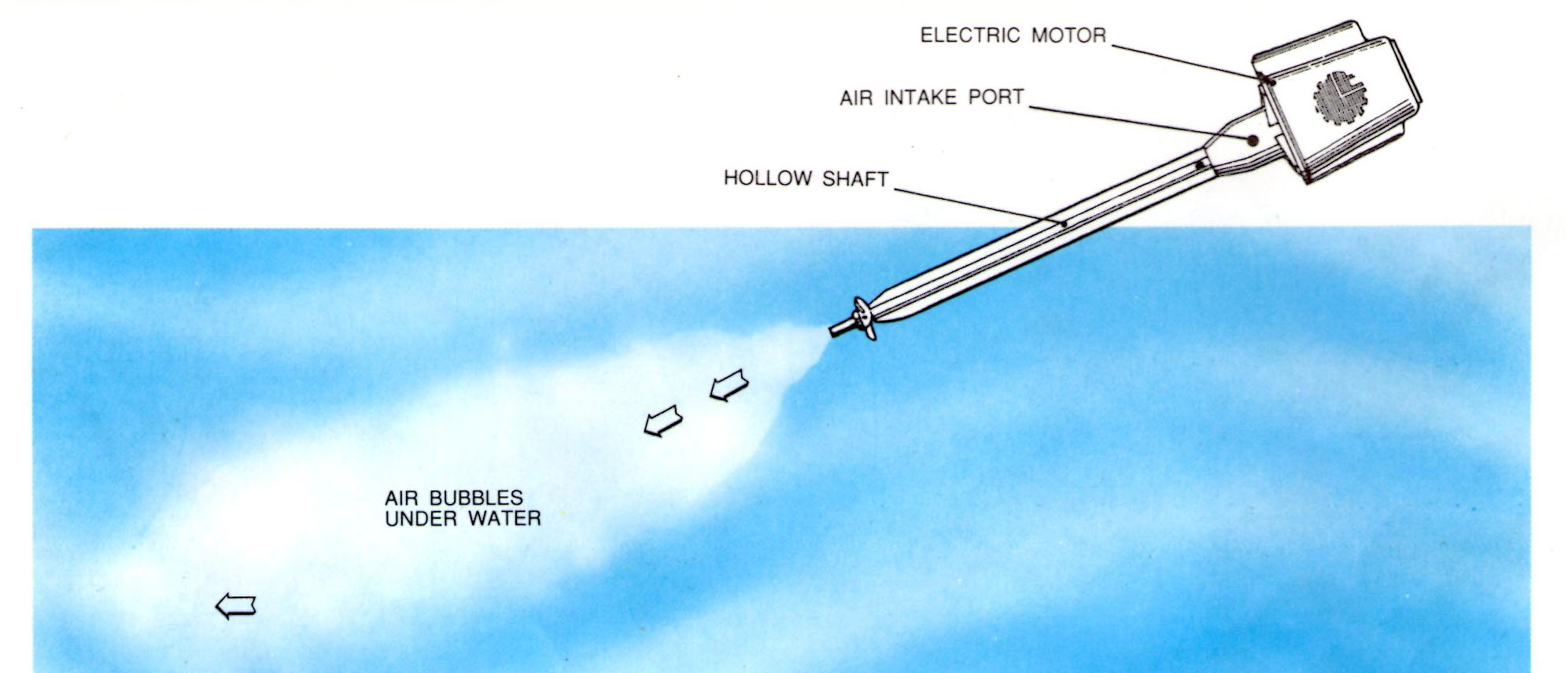

HOW THE AERATOR WORKS

The JET-MIX is mounted at an adjustable angle in the water with the motor portion and air intake above the surface, and the propeller portion below the surface. The motor rotates, turning the hollow shaft which turns the propeller. This pushes water at a high velocity through and near the propeller blades, creating a partial vacuum at the end of the shaft. Atmospheric air above the waterline is drawn in through the air intake port and into the hollow shaft. Turbulance and flow created by the propeller breaks up the air bubbles, mixes the basin and disperses oxygen. The horizontal water movement maximizes bubble hang time maximizing oxygen transfer.

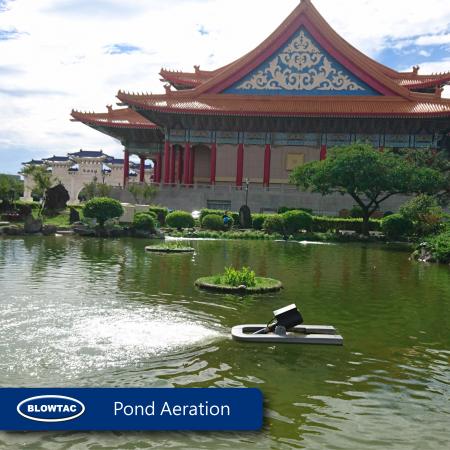

AERATED LAGOONS

As its unique strong mixing action in horizontal

flow,the Aerator is considered to be the ideal

tools formost aerated lagoon with various depth.

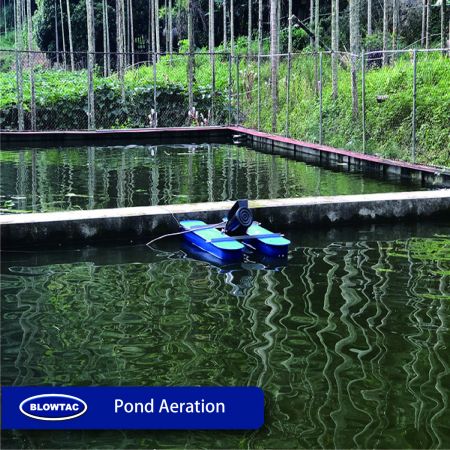

ΟΧΙDΑΤΙΟΝ DΙΤCΗ

The Oxidation ditches are mostly seen in activated

sludge process.The Aerator is specially effective

in oxidation ditch because of its high horizontal

mixing pattern ofbest design.

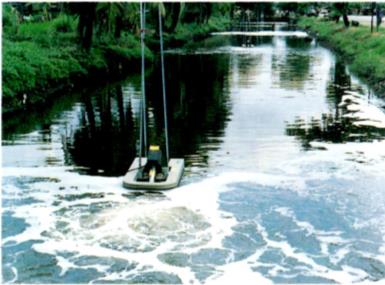

RIVER AND CANAL RESTORATIONS

The river and canal polluted by the residents will be

restored by using the Aerator.The boosting of

D.O.levels for aquatic life can improve water quality

in lake,canal or reservoir and upgrade the surrounding

ecosystem.

ΑΕΡΑΤΙΟΝ ΤΑΝΚ

The Aerator can be utilized in conventional tank

for activated sludge or digester. The units with

proper placement in tank can provide the

complete mix and eliminate dead spots.

Dimension

| Model | Output | Oxygen Transfer Rate | Air Volume | Mixing Volume | Working Depth | Unit Weight | |

|---|---|---|---|---|---|---|---|

| HP | kW | kg-O2/hr | M³/min | M³ | M | Kg | |

| JM-005 | 1/2 | 0.40 | 0.75 | 0.21 | 40-100 | 0.5-1.5 | 44.0 |

| JM-010 | 1 | 0.75 | 1.49 | 0.42 | 80-200 | 1.5-2.5 | 48.0 |

| JM-020 | 2 | 1.5 | 2.98 | 0.83 | 160-400 | 1.5-2.5 | 52.0 |

| JM-030 | 3 | 2.25 | 4.47 | 1.26 | 240-600 | 1.5-2.5 | 58.0 |

| JM-050 | 5 | 3.7 | 7.45 | 2.09 | 400-1,000 | 1.5-3.5 | 65.0 |

| JM-075 | 7.5 | 5.5 | 11.18 | 3.13 | 600-1,500 | 1.5-3.5 | 76.6 |

| JM-100 | 10 | 7.5 | 14.90 | 4.17 | 800-2,000 | 2-5 | 104.3 |

| JM-150 | 15 | 11 | 22.35 | 6.26 | 1,150-2,500 | 2-5 | 135.1 |

| JM-200 | 20 | 15 | 29.80 | 8.35 | 1,500-3,800 | 2-5 | 156.4 |

| JM-250 | 25 | 18.5 | 37.25 | 10.44 | 1,750-4,400 | 3-6 | 225.8 |

| JM-300 | 30 | 22 | 44.70 | 12.53 | 2,100-5,100 | 3-6 | 240.2 |

| JM-400 | 40 | 30 | 59.80 | 16.70 | 2,800-6,400 | 3-6 | 322.7 |

| JM-500 | 50 | 37 | 74.50 | 20.88 | 3,500-8,000 | 4-7 | 356.0 |

Press Release

2025 TAIWAN INT’L WATER WEEK (10/29~10/31)BOOTH NO.: L0917

2025 TAIWAN INT’L WATER WEEK (10/29~10/31)BOOTH NO.: L0917Our company will be participating in the 2025 Taiwan International Water Week from October 29th to 31st, located on the 4th floor of Hall 1 at the Taipei Nangang Exhibition Center. We will...

Read More Taiwan Expo 2025 in Philippines (9/17~9/19) SMX Convention Center Manila Function Room 1-3

Taiwan Expo 2025 in Philippines (9/17~9/19) SMX Convention Center Manila Function Room 1-3Our company will be participating in theTaiwan Expo 2025 in Philippines from September 17th to September 19th, located SMX Convention Center Manila Function Room 1-3

Read More

We will be showcasing...

English

English